Product overview

For a century, the principle of power transformers has not changed. As the years go by, advanced production equipment is becoming more and more perfect. The amorphous alloy wound core transformer produced by our company is made of a new type of magnetic conductive material - amorphous alloy winding core . transformer Compared with a silicon steel core transformer, its no-load loss is reduced by about 80%, and the no-load current is reduced by about 80%. It is a distribution transformer with ideal energy-saving effect at present, and is especially suitable for rural power grids and developing areas. Where the load rate is low. Amorphous alloy iron core distribution transformers have low no-load loss, obvious advantages in energy saving and environmental protection, and are in line with the industrial policy of "saving resources . Oil-immersed transformers can also reduce the emission of harmful gases such as CO, SO, NOx and are called "green materials" in the 21st century .

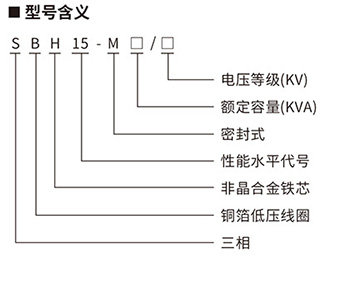

Model and features

Product conformity

GB 10994.1-2013 "Power transformers Part I: General Provisions"Technical parameter

SH15-M Technical specifications

|

额定容量 (KVA) |

电压组合及分接范围(kV) |

联结组标号 Lable of connecting group |

空载损耗 (W) |

负载损耗 (W) |

空载电流 (%) |

短路阻抗 (%) |

||

|

高压(kV) |

高压分接范围(%) High voltage tapping range |

低压(kV) |

||||||

|

30 |

6 |

±5±2x2.5 |

0.4 |

Dyn11 |

33 |

600 |

1.70 |

4.0 |

|

50 |

43

|

870

|

1.30

|

|||||

|

63 |

50

|

1040

|

1.20

|

|||||

|

80 |

60

|

1250

|

1.10

|

|||||

|

100 |

75

|

1500

|

1.00

|

|||||

|

125 |

85

|

1800

|

0.90

|

|||||

|

160 |

100

|

2200

|

0.70

|

|||||

|

200 |

120

|

2600

|

0.70

|

|||||

|

250 |

140

|

3050

|

0.70

|

|||||

|

315 |

170

|

3650

|

0.50

|

|||||

|

400 |

200 |

4300 |

0.50 |

|||||

|

500 |

240

|

5150

|

0.50

|

|||||

|

630 |

320 |

6200 |

0.30 |

4.5 |

||||

|

800 |

||||||||

|

1000 |

||||||||

|

1250 |

530 |

12000 |

0.20 |

|||||

|

1600 |

630 |

14500 |

0.20 |

|||||

|

2000 |

750 |

17400 |

0.20 |

5 |

||||

|

2500 |

900 |

20200 |

0.20 |

|||||

SH16-M技术参数

|

型号 |

电压组合(kV) |

联结 方式 Conn- |

空载 损耗 (W) No- |

负载 损耗 (W) |

空载 电流 (%) No- |

阻抗 电压 (%) Impe- |

外形尺寸(mm) |

安装底座中心 |

油重 (kg) |

总重 (kg) |

||||

|

高压 |

高压分 接范围 (%) |

低压 |

L |

H |

B |

|||||||||

|

SH16-M-50/10 |

6 |

±2 x2.5 |

0.4 |

Dyn11 |

38 |

870 |

0.9 |

4.0 |

950 |

1040 |

620 |

400x550/4-Ø14 |

160 |

680 |

|

SH16-M-100/10 |

58 |

1500 |

0.7 |

4.0 |

1060 |

1070 |

770 |

400x660/4-Ø14 |

190 |

890 |

||||

|

SH16-M-160/10 |

78 |

2200 |

0.5 |

4.0 |

1060 |

1150 |

930 |

400x870/4-Ø19 |

250 |

1190 |

||||

|

SH16-M-200/10 |

90 |

2600 |

0.5 |

4.0 |

1110 |

1170 |

930 |

550x870/4-Ø19 |

270 |

1300 |

||||

|

SH16-M-250/10 |

110 |

3050 |

0.5 |

4.0 |

1180 |

1180 |

1010 |

550x870/4-Ø19 |

300 |

1460 |

||||

|

SH16-M-315/10 |

130 |

3650 |

0.4 |

4.0 |

1180 |

1180 |

1010 |

550x870/4-Ø19 |

240 |

1400 |

||||

|

SH16-M-400/10 |

160 |

4300 |

0.4 |

4.0 |

1200 |

1180 |

1010 |

550x870/4-Ø19 |

280 |

1660 |

||||

|

SH16-M-500/10 |

190 |

5150 |

0.4 |

4.0 |

1270 |

1200 |

1160 |

660x1070/4-Ø19 |

300 |

1950 |

||||

|

SH16-M-630/10 |

230 |

6200 |

0.3 |

4.5 |

1450 |

1330 |

1240 |

820x1070/4-Ø14 |

480 |

2450 |

||||

|

SH16-M-800/10 |

280 |

7500 |

0.3 |

4.5 |

1520 |

1460 |

1380 |

820x1070/4-Ø19 |

520 |

2900 |

||||

|

SH16-M-1000/10 |

330 |

10300 |

0.3 |

4.5 |

1720 |

1510 |

1460 |

820x1070/4-Ø19 |

680 |

3500 |

||||

|

SH16-M-1250/10 |

390 |

12000 |

0.2 |

4.5 |

1785 |

1690 |

1330 |

820x1070/4-Ø19 |

800 |

3980 |

||||

|

SH16-M-1600/10 |

470 |

14500 |

0.2 |

4.5 |

1880 |

1970 |

1380 |

820x1070/4-Ø19 |

850 |

5300 |

||||

|

SH16-M-2000/10 |

570 |

17400 |

0.2 |

5.0 |

2080 |

1965 |

1540 |

820x1070/4-Ø19 |

1310 |

6150 |

||||

|

SH16-M-2500/10 |

680 |

20200 |

0.2 |

5.0 |

2400 |

2350 |

1500 |

820x1070/4-Ø19 |

1850 |

8200 |

||||

■Product insulation level

|

电压等级 |

设备最高电压有效值 |

额定短时工频耐受电压有效值kV/分钟 Effective value of rated short duration power frequency withstand |

额定雷电冲击耐受电压全波峰值(kV) Full wave peak value of rated lightning impulse withstand voltage |

|

≤1 |

≤1.1 |

5 |

- |

|

6 |

6.9 |

25 |

75 |

|

10 |

11.5 |

35 |

95 |

|

20 |

23 |

50 |

125 |

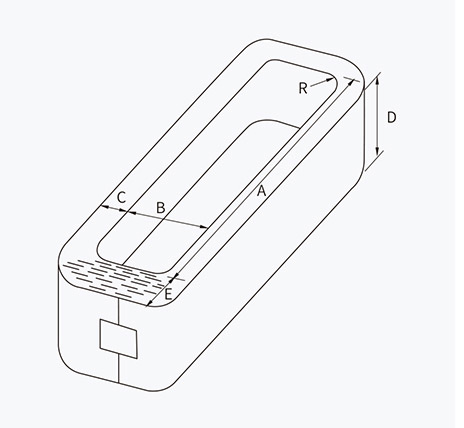

Overall dimension